Bernoulli’s Apparatus

Technical Specifications:

Flow channel: 350 mm length, made of acrylic conduit

Peizometer tubes: 9 Nos. Placed equal spaced at 5 cm mounted on graduated board

Constant head tank: 1 No. Size (300mm x 300mm x 450mm), Capacity 30 litres

Measuring tank: 300mm x 300mm x 300mm

Sump tank: 600mm x 300mm x 300mm, Capacity 60 litres

Pipings and fittings: GI material used

Valves: 2 Nos. For drain, 1 No. For water control, 1 No. For bypass

Stop watch: Electronic

Pump: 0.5 HP single phase, 220 VAC + 10% CG make

Power requirement: 220 VAC + 10%, 50 Hz

Learning Objectives:

The primary objective of Bernuolli’s experiment is to investigate the validity of the Bernoulli equation when it is applied to a steady flow of water through a tapered duct.

Reynold’s Apparatus

Technical Specifications:

Tube: Clear acrylic 800 mm length, 32 mm outer diameter and 25 mm inner diameter

Dye vessel: Material- Stainless steel, 1 litre capacity

Constant head tank: 1 No. Size (300mm x 300mm x 450mm), Capacity 30 litres

Measuring tank: 300mm x 300mm x 300mm

Sump tank: 600mm x 300mm x 300mm, Capacity 60 litres

Pipings and fittings: GI material used

Valves: 2 Nos. For drain, 1 No. For water control, 1 No. For bypass

Stop watch: Electronic

Pump: 0.5 HP single phase, 220 VAC + 10% (ISI)

Setup fitted on angle iron frame of size 1280mm x 330mm x 910mm

Power requirement: 220 VAC + 10%, 50 Hz

Learning Objectives:

The primary objectives of Reynold’s experiment are:

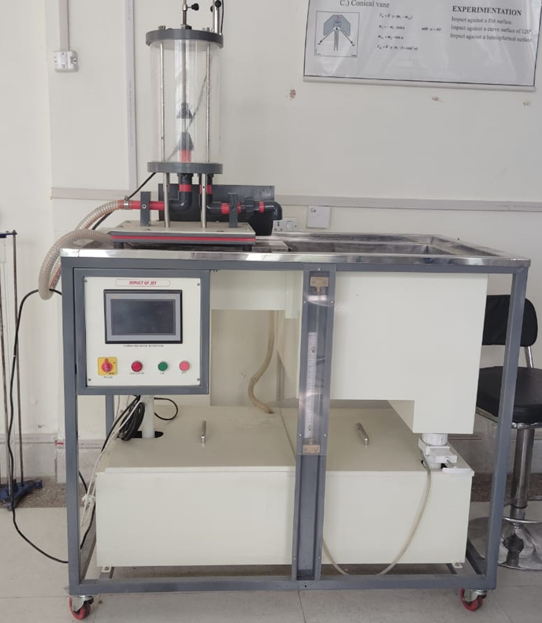

Impact of Jet Apparatus

Technical Specifications:

Net dimensions and weight: 740 mm high x 420 mm wide x 310 mm and 6 kg

Approximate packed dimensions and weight: 0.176 m3 and 13 kg

Flat plate: 74 mm diameter, normal to and coincident with the jet axis

Hemispherical plate: 60 mm diameter

Conical plate: 75 mm diameter, 120°

Angled plate: 75 mm diameter, 30°

Ancillaries (included): All necessary pipe clips and tubing

Power requirement: 220 VAC + 10%, 50 Hz

Learning Objectives:

The primary objectives of the impact of jet apparatus are:

-

To investigate the reaction forces produced by the change in momentum of a fluid flow when a jet of water strikes a flat plate or a curved surface, and

-

To compare the results from this experiment with the computed forces by applying the momentum equation.

Metacentric Height Apparatus

Technical Specifications:

Net dimensions: 170 mm x 380 mm x 250 mm with a horizontal guide bar for aliding weight.

Water tank: Size 600 x 400 x 400 mm (Approx.)

Distance from pontoon centre line to added weight: 123 mm

Centre of gravity of pontoon: 125 mm approx. from outer surface of vessel base

Weight of vessel: 3 kg approx.

Height of mast loading position above water surface of vessel base: 790 mm

Max. angle of heel: ±130

A set of weights is supplied with the apparatus

Learning Objectives:

The primary objectives of the metacentric height apparatus are:

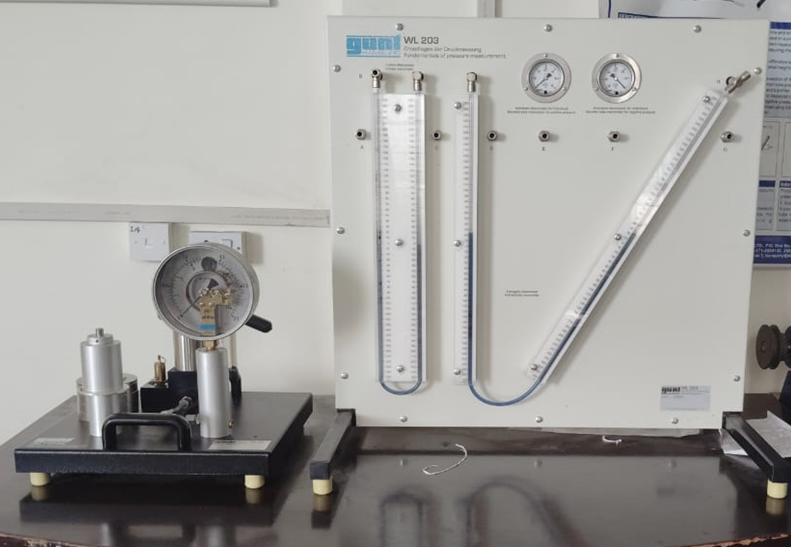

Pressure Measurement Devices

Technical Specifications:

Inclined tube manometer angle: 30°

Measuring ranges: 0 - 500mmWC (U-tube manometer)

0 - 500mmWC (inclined tube manometer)

0 - ±60mbar (Bourdon tube pressure gauge)

Dimensions: 750mm x 610mm x 810mm (LxWxH)

Calibration device: 410mm x 410mm x 410mm (LxWxH)

Total weight: approx. 40 kg

Learning Objectives:

The primary objectives of these pressure measurement devices are:

i) Direct method with U-tube manometer and inclined tube manometer

ii) Indirect method with Bourdon tube pressure gauge

Flow Measurement Devices

Technical Specifications:

Venturimeter: Material – Clear acrylic, 2.54 cm diameter pipe

Orifice meter: Material – Clear acrylic, 2.54 cm diameter pipe

Water circulation: FHP pump, Crompton/ Sharp make

Flow measurement: Using measuring tank, Capacity 30 litres

Sump tank: Capacity 50 litres

Stop watch: Electronic

Electricity supply: Single phase, 220 VAC, 50 Hz.

Learning Objectives:

The primary objectives of the flow measurement devices are:

-

To determine the coefficient of discharge through venturimeter and orifice meter

-

To measure discharge through venturimeter and orifice meter, and

-

To obtain the relationship between Reynolds number and the coefficient of discharge.

Falling Ball Viscometer

Technical Specifications:

Viscosity Range: 0.5 - 7x104 mPa-s (cP)

Falling Time-Lower Limit: 60 s for Ball No.1

30 s for Ball Nos. 2,3,4,5 and 6

Falling Time-Upper limit: 300 s

Materials with viscosity>7x104 mPa-s require running time of over 300 s.

Measuring Distance: 100 mm (50 mm between adjacent ring marks) in both directions

Fall Tube Inner Diameter: 15.94mm ± 0.01mm

Set of Balls: 6 balls

Working Angle: KF30: 80° (DIN position); KF40: 80°, 70°, 60°, 50°

Temperature Range: -5°C - +150°C

Sample Volume: 40 mL

Learning Objectives:

The primary objectives of the falling ball viscometer are:

-

To determine the density of a sphere

-

To determine the density and viscosity of an unknown fluid.

-

To determine the uncertainty in the density and viscosity measurements

-

To identify any discrepancies within the experimental results and provide a plausible explanation for the observed discrepancies.